Roller Chain Guide Rails

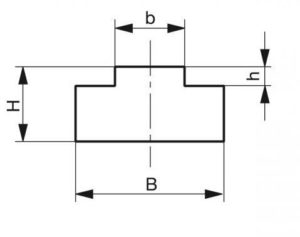

Single Roller Chain Guides

The action of the chain guide guides the fixed support, reduces wear, reduces noise and prolongs service life. Self-lubricating, high wear resistance, low sliding friction coefficient, strong impact resistance and pressure stability, in line with food hygiene requirements, low noise, insulation and thermal stability.

In the high-speed and heavy-duty power transmission, some chain guides also have the effect of buffering, damping and improving the dynamic function of the shafting. The chain guide consists of two halves, which are connected to the drive shaft and the driven shaft. Most of the general power machines are connected to the working machine by means of chain guides, which are the most commonly used connecting parts for the shafting of mechanical products.

Chain no. DIN 8187 | Chain dimensions in inches | B | H | b | h |

DIN 8187 – 06B-1 | 3/8″x7/32″ | 15 | 10 | 5.4 | 1.5 |

DIN 8187 – 083-1 | 1/2″x3/16″ | 15 | 10 | 4.5 | 1.5 |

DIN 8187 – 085-1 | 1/2″ x 1/4″ | 20 | 10 | 6.2 | 2.2 |

DIN 8187 – 08B-1 | 1/2″ x 5/16″ | 20 | 10 | 7.4 | 2.2 |

DIN 8187 – 08B-1 | 1/2″ x 5/16″ | 20 | 15 | 7.4 | 2.2 |

DIN 8187 – 08B-1 | 1/2″ x 5/16″ | 20 | 20 | 7.4 | 2.2 |

DIN 8187 – 08B-1 | 1/2″ x 5/16″ | 20 | 30 | 7.4 | 2.2 |

DIN 8187 | 5/8″ x 1/4″ | 20 | 10 | 6.2 | 2.6 |

DIN 8187 – 10B-1 | 5/8″ x 3/8″ | 20 | 10 | 9.3 | 2.6 |

DIN 8187 – 10B-1 | 5/8″ x 3/8″ | 20 | 15 | 9.3 | 2.6 |

DIN 8187 – 10B-1 | 5/8″ x 3/8″ | 20 | 20 | 9.3 | 2.6 |

DIN 8187 – 10B-1 | 5/8″ x 3/8″ | 20 | 30 | 9.3 | 2.6 |

DIN 8187 – 12B-1 | 3/4″ x 7/16″ | 25 | 10 | 11.3 | 2.4 |

DIN 8187 – 12B-1 | 3/4″ x 7/16″ | 25 | 15 | 11.3 | 2.4 |

DIN 8187 – 12B-1 | 3/4″ x 7/16″ | 25 | 20 | 11.3 | 2.4 |

DIN 8187 – 12B-1 | 3/4″ x 7/16″ | 25 | 30 | 11.3 | 2.4 |

DIN 8187 – 16B-1 | 1″ x 17 mm | 40 | 15 | 16 | 3.5 |

DIN 8187 – 16B-1 | 1″ x 17 mm | 40 | 20 | 16 | 3.5 |

DIN 8187 – 16B-1 | 1″ x 17 mm | 40 | 30 | 16 | 3.5 |

DIN 8187 – 20B-1 | 1 1/4″ x 3/4″ | 45 | 15 | 18 | 4.2 |

DIN 8187 – 24B-1 | 1 1/2″ x 1″ | 60 | 15 | 24 | 5.5 |

DIN 8187 – 28B-1 | 1 3/4″ x 31 mm | 75 | 20 | 30 | 6.8 |

DIN 8187 – 32B-1 | 2″ x 31 mm | 80 | 20 | 30 | 7.7 |

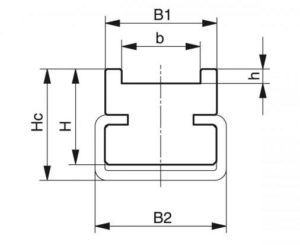

| Chain dimensions in inches | C profile | B1 | B2 | H | Hc | b | h |

| 3/8″ x 7/32″ | C3 | 17 | 20 | 14 | 17 | 5.4 | 1.5 |

| 1/2″ x 3/16″ | C3 | 17 | 20 | 14 | 17 | 4.5 | 1.5 |

| 1/2″ x 1/4″ | C3 | 17 | 20 | 14 | 17 | 6.2 | 2.2 |

| 1/2″ x 5/16″ | C1 | 20 | 24 | 10 | 11 | 7.4 | 2.2 |

| 1/2″ x 5/16″ | C3 | 17 | 20 | 14 | 17 | 7.4 | 2.2 |

| 5/8″ x 1/4″ | C3 | 17 | 20 | 14 | 17 | 6.2 | 2.6 |

| 5/8″ x 3/8″ | C3 | 17 | 20 | 14 | 17 | 9.3 | 2.6 |

| 3/4″ x 7/16″ | C3 | 20 | 20 | 14 | 17 | 11.3 | 2.4 |

| 3/4″ x 7/16″ | C5 | 24 | 28 | 14 | 18 | 11.3 | 2.4 |

| 1″ x 17 mm | C5 | 24 | 28 | 14 | 18 | 16 | 3.5 |

| 1 1/4″ x 3/4″ | C5 | 28 | 28 | 14 | 18 | 18 | 4.2 |

| 1 1/2″ x 1″ | C9 | 33 | 38 | 23 | 30 | 24 | 5.5 |

| 1 3/4″ x 31 mm | C9 | 38 | 38 | 23 | 30 | 30 | 6.8 |

| 2″ x 31 mm | C9 | 38 | 38 | 23 | 30 | 30 | 7.7 |

| 2″ x 31 mm | C12 | 60 | 60 | 25 | 35 | 30 | 7.7 |

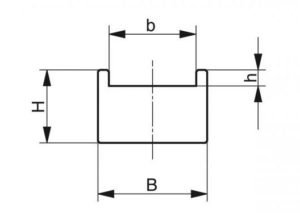

| Chain dimensions in inches | B | H | b | h |

| 1/2″ x 3/16″ | 15 | 10 | 12 | 2.2 |

| 3/8″ x 5/32″ | 15 | 10 | 12 | 2.2 |

C profile | B1 | B2 | H | Hc | b | h |

C3 | 17 | 20 | 14 | 17 | 12 | 2.2 |

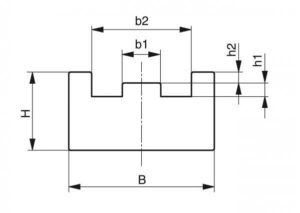

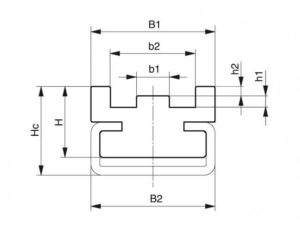

Chain dimensions in inches | B | H | b1 | b2 | h1 | h2 |

3/8″ x 7/32″ | 20 | 10 | 3.8 | 13 | 1.5 | 1.1 |

1/2″ x 3/16″ | 20 | 10 | 3 | 12.4 | 1.6 | 1.4 |

1/2″ x 1/4″ | 22 | 10 | 4.5 | 15.1 | 2.2 | 1.6 |

1/2″ x 5/16″ | 25 | 15 | 5.7 | 16.3 | 2.2 | 1.6 |

5/8″ x 1/4″ | 25 | 15 | 4.1 | 16.1 | 2.6 | 2.1 |

5/8″ x 3/8″ | 28 | 15 | 7.4 | 19.2 | 2.6 | 2.1 |

3/4″ x 7/16″ | 30 | 20 | 9.2 | 21.8 | 2.4 | 2.8 |

1″ x 17 mm | 42 | 25 | 15 | 35 | 3.5 | 3.3 |

1 1/4″ x 3/4″ | 50 | 25 | 16.8 | 40 | 4.2 | 4 |

Chain dimensions in inches | C profile | B1 | B2 | H | Hc | b1 | b2 | h1 | h2 |

3/8″ x 7/32″ | C3 | 20 | 20 | 14 | 17 | 3.8 | 13 | 1.5 | 1.1 |

1/2″ x 3/16″ | C3 | 20 | 20 | 14 | 17 | 3 | 12.4 | 1.6 | 1.4 |

1/2″ x 1/4″ | C3 | 22 | 20 | 14 | 17 | 4.5 | 15.1 | 2.2 | 1.6 |

1/2″ x 5/16″ | C3 | 25 | 20 | 16 | 20 | 5.7 | 16.3 | 2.2 | 1.6 |

5/8″ x 1/4″ | C3 | 25 | 20 | 16 | 20 | 4.1 | 16.1 | 2.6 | 2.1 |

5/8″ x 3/8″ | C5 | 28 | 28 | 16 | 20 | 7.4 | 19.2 | 2.6 | 2.1 |

3/4″ x 7/16″ | C5 | 30 | 28 | 18 | 22 | 9.2 | 21.8 | 2.4 | 2.8 |

1″ x 17 mm | C9 | 42 | 38 | 25 | 30 | 15 | 35 | 3.5 | 3.3 |

1 1/4″ x 3/4″ | C9 | 50 | 38 | 30 | 35 | 16.8 | 40 | 4.2 | 4 |

1: The biggest advantage of the chain guide is its wear resistance. Among its many performance characteristics, its wear resistance is particularly outstanding. The wear resistance of the chain guide is much stronger than the wear resistance of some metals.

2: Another property of the chain guide is impact resistance. The chain is greatly protected to a certain extent during the operation, and the impact of the chain on the equipment is reduced.

3: Chain guides also have an important performance feature that is self-lubricating. This feature greatly reduces the wear of the chain and greatly extends the life of the chain.

4: Chain guide rails also have stable chemical properties, which are resistant to acid, alkali and salt corrosion. This feature greatly expands the use environment of the chain guide rail. Of course, it also has non-stick properties and is not easy to get wet.

5: Super low temperature resistance, the temperature of the chain guide is between +80~-200. This shows that the chain guide can work even in an ultra-low environment.

6: The chain guide is colorless and odorless, green and safe, and can be used with confidence.

Related UHMW Guide Rails

Contact Us

Sales Manager: Tom Lee

Email: sales@plastic-guide-rails.com

Tel:+86-372-6211478

Mobile: +86-15937282819 (Wechat & Whatsapp)

Get a Quote