Feed Screws - CNC Machined Parts

Feed Screws Introduction

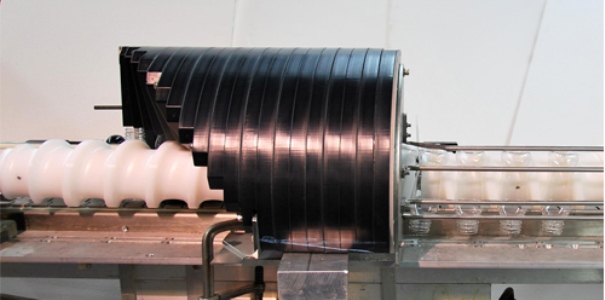

Design and CNC machining of bottle screw for filling machine parts

In the beverage filling process, it is necessary to smoothly convey the packaging container (bottle) at a fixed distance to the packaging station, and the device for accomplishing this requirement is called a distance separation timing supply device. It consists of a bottle screw and a side guide, which is installed at the end of the container supply system near the packaging machine, and is connected with the star wheel of the transfer container. The feeding screw is driven by the transmission system to rotate at a constant speed, and the container sent by the conveying device is introduced into the spiral groove, and the container is advanced by the spiral groove, and is separated by the spiral groove, and is sent to the star wheel by the outlet end. The transfer device composed of the guide plates can realize the purpose of sequentially feeding the containers in sequence. Each time the bottle screw is rotated, a container is introduced from the inlet of the screw into the bottle, the container in the spiral groove advances by a pitch, and the outlet end of the screw discharges a container. A certain gear ratio is maintained between the rotational speed of the screw and the actuator of the packaging machine loading device, thereby indirectly fulfilling the requirements of the timing supply container.

Feed Screws Application

- Bottle filling – brewery, soft drinks, water etc

- Plastic containers

- Shampoo bottle filling

- Food Processing

- Paper Product packaging

- Wineries

- Bottle & Beverage

- Cans

- Food

- Packaging

- Shampoo

- Conveyor

Related UHMW Products

Contact Us

Sales Manager: Tom Lee

Email: sales@plastic-guide-rails.com

Tel:+86-372-6211478

Mobile: +86-15937282819 (Wechat & Whatsapp)

Get a Quote